Climate Concrete 1.0

Development of a bioclimatic concrete prefabricated facade panel

Project details

Years: 2016-17

Firm role: Architectural design and design of bioclimatic facades

Category: University and company

The development of the bioclimatic concrete façade panel originated from the collaboration with Cemex Global R&D on the selective subject at the Barcelona School of Architecture, International University of Catalonia, called Climate Concrete.

Based on educational modules and a workshop in the Swiss laboratory of Cemex Global R&D, the students had the opportunity to learn about various types and properties of high-performance and innovate concrete. The aim was to develop innovative applications of concrete, taking advantage of its intrinsic properties, other than the purely mechanical properties normally considered in construction. This first year of the workshop (2016/2017) was dedicated to porous concrete.

The possibility to apply the concept came with the Wellness Hub project, located in Monterrey, México, with the objective to reach the Net Zero Energy standard. The climate of Monterrey is a complex one, with a high cooling demand in the summer period, which creates a need for passive cooling strategies.

The building is composed around a large central patio, concentrating most of the horizontal and vertical communications, all of them at the exterior.

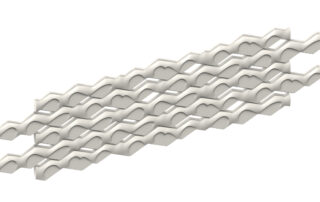

The application of the porous concrete PerviaTM on the façade adjacent to these communications as a solar shading gave an opportunity to exploit the bioclimatic characteristics of concrete and provide an additional cooling. The structural resistance of the façade panel is ensured by the external panel layer made of high performance concrete ResiliaTM.

The performance of the façade panel is based on 5 concepts- the solar shading including the self-shading of the panel to reduce the quantity of the received solar radiation, the reflectance of solar radiation, the thermal inertia, reduced thermal transfer by conduction and most particularly on the evaporative cooling and other effects of introduction of a water feature to the panel.

The effects of the above-mentioned strategies have been studied by simulations and real-scale testing processes, giving satisfactory results. Following the successful testing, the façade was implemented in the OUM Wellness project in 2023, covering its main façade. The production was assured by Mexican manufacturing company Kinetica, which managed to create impeccable reusable molds to be filled in by the two concrete mixtures, specifically designed for the project by the Cemex Global R&D team. The full technology has been implemented in a strategic location, with a high concentration of visitors, and will be further tested.