Insularis frames using D.fab technology

Insulating solution for architectural openings

Architectural openings often suffer from thermal break problems. Although concrete seems like an unexpected choice to solve these problems, thanks to innovative concrete mixes, there are applications where this strategy is a perfect fit.

Cemex Global R&D has developed an innovative construction technique – within its portfolio of digital manufacturing technologies (D.fab) – called Digital Morphing, which takes advantage of and combines advanced Computer Numerical Control (CNC) processes with the insulating properties of its InsularisTM concrete to manufacture architectural elements that improve thermal insulation on facades.

Our team has identified great potential in this solution. On the one hand, the insulating concrete, InsularisTM, which in addition to having a thermal conductivity similar to that of traditional insulating materials also has good mechanical resistance, can be used on the facades of buildings, providing the necessary thermal resistance to the building and , at the same time, taking advantage of one of the main architectural qualities of concrete: the fact that it does NOT need additional layers and can remain unprotected, visible, and attractive. Additionally, this is a fire-resistant mineral-based material, which contributes to fire protection.

By creating synergy with this material, the digital manufacturing used by Cemex allows for high-precision forming operations, but with great flexibility, offering total customization where the limit is your imagination.

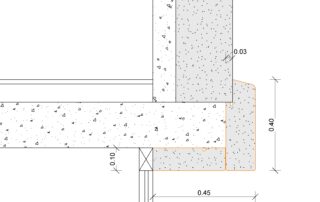

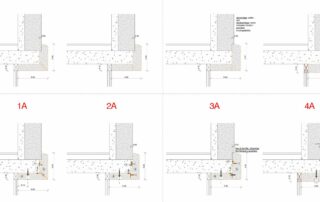

There are multiple applications of this technology. The first one we have explored is using it as an insulating exterior frame for architectural openings. Based on the needs of the pilot project for single-family homes in Barcelona, an entrance frame was proposed to resolve the detail between the floor structure and the wall, avoiding thermal losses with the additional thermal insulating material.

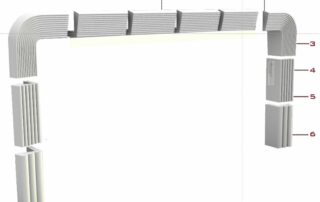

As mentioned above, this technology allows for customization of system components. From a practical point of view, lighting or an entry system can be easily and seamlessly integrated into the InsularisTM components. On the other hand, from an aesthetic point of view, any individual 3D pattern can be milled into the volume of the components, allowing building users to identify with their building and also improve orientation in the urban environment.

Ultimately, the technology was successfully implemented in a pilot project, where the residential building has a customized entrance frame. It is made up of individually fixed flat components, installed in a continuous frame visible from the front and bottom. The pilot project validated the application both in new constructions and in energy modernizations and rehabilitations of existing buildings.